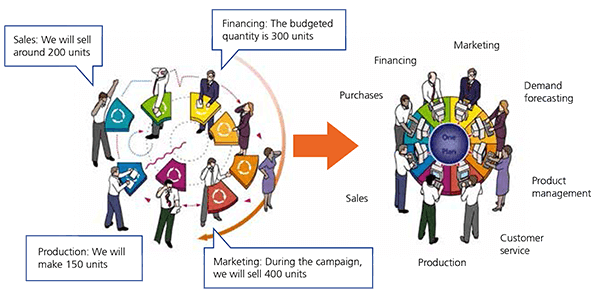

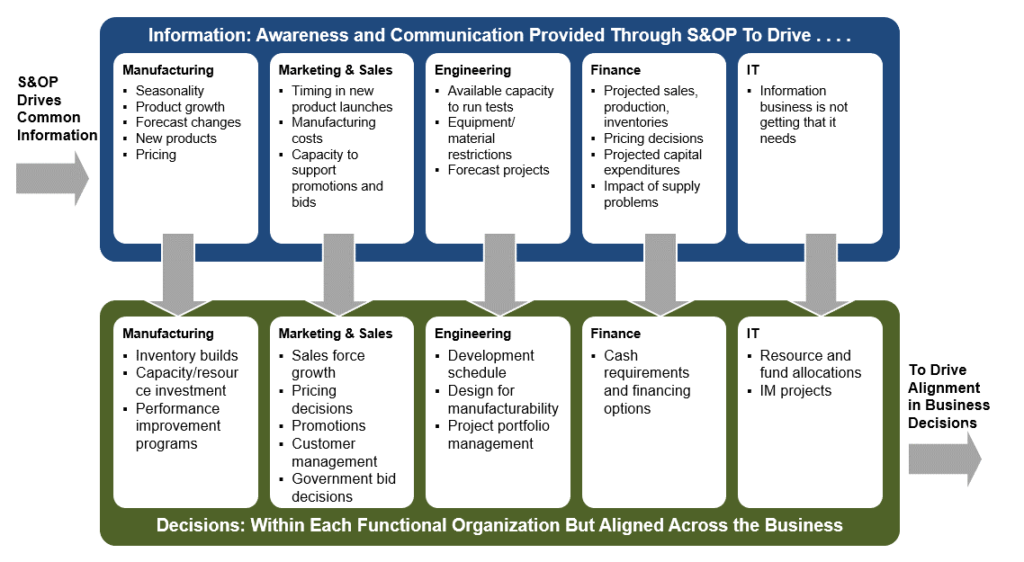

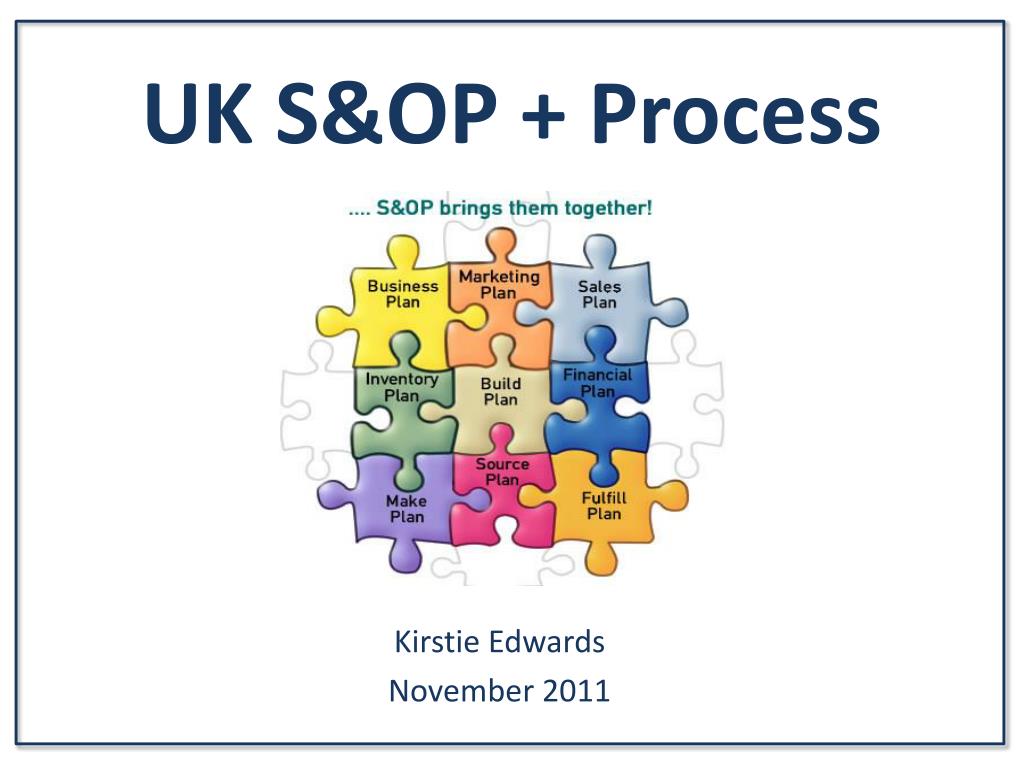

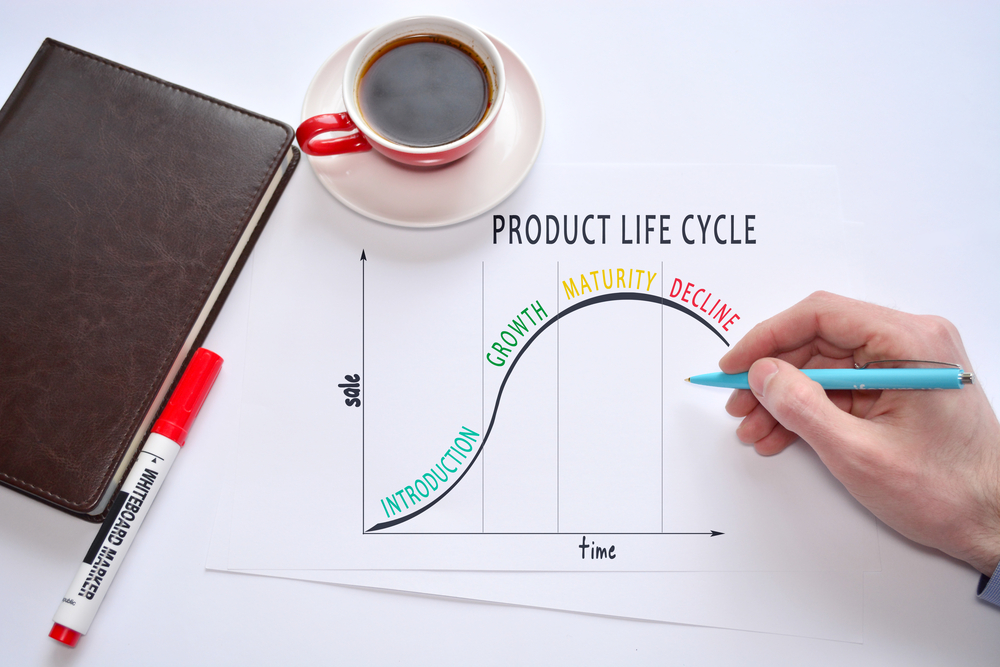

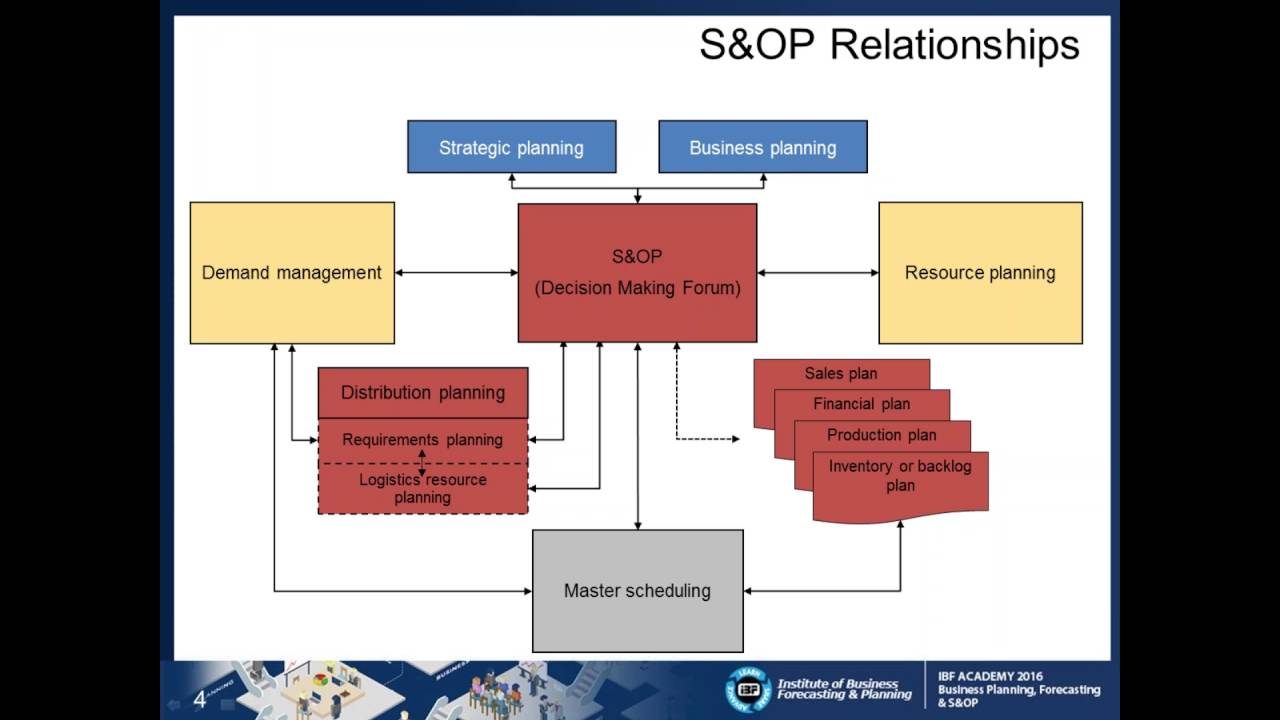

The process brings together all the plans for the business (sales, marketing, development, manufacturing, sourcing, and financial) into one integrated set of plans APICS Dictionary, 14th edition S&OP Processes Planning Objectives of S&OP ‐ S&OP supports and measures the progress of the entire organization in meeting the Product review and lifecycle processes are not new and exist in most organizations but they are frequently independent of the S&OP process I f the product review cycle is not a part of your existing S&OP process, it should be Let's look at some compelling reasons to integrate the product review into your S&OP process A good executive S&OP process will have all these characteristics If it does, S&OP should be improving your demand plan If it doesn't, now is the time to get the process tuned up and break out of the OS&P cycle Contact us to find out how DBM is a global thought leader with over years of S&OP consulting experience

Going Global With Sales And Operations Planning Ppt Video Online Download

How to improve s&op process

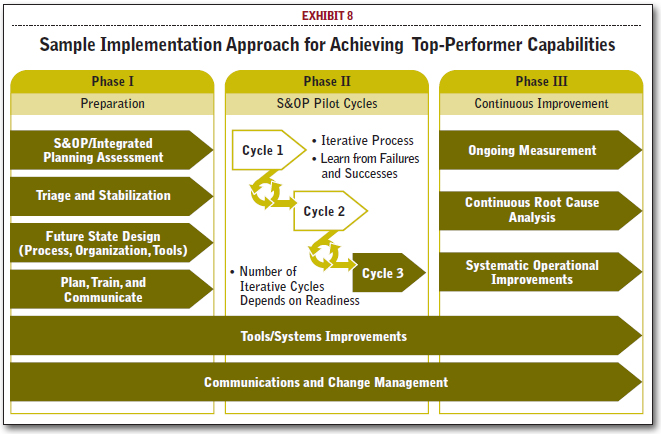

How to improve s&op process- S&OP Implementation Roadmap 1 S&OP Implementation Roadmap Implement S&OP, as a critical business process, championed by a crossfunctional team ofThe Objective of the S&OP Process The overall objective of the S&OP process is to agree on an aligned set of feasible functional plans and targets for the next 18 – 24 periods, consistent with

What Is S Op Sales And Operations Planning Explained Anaplan

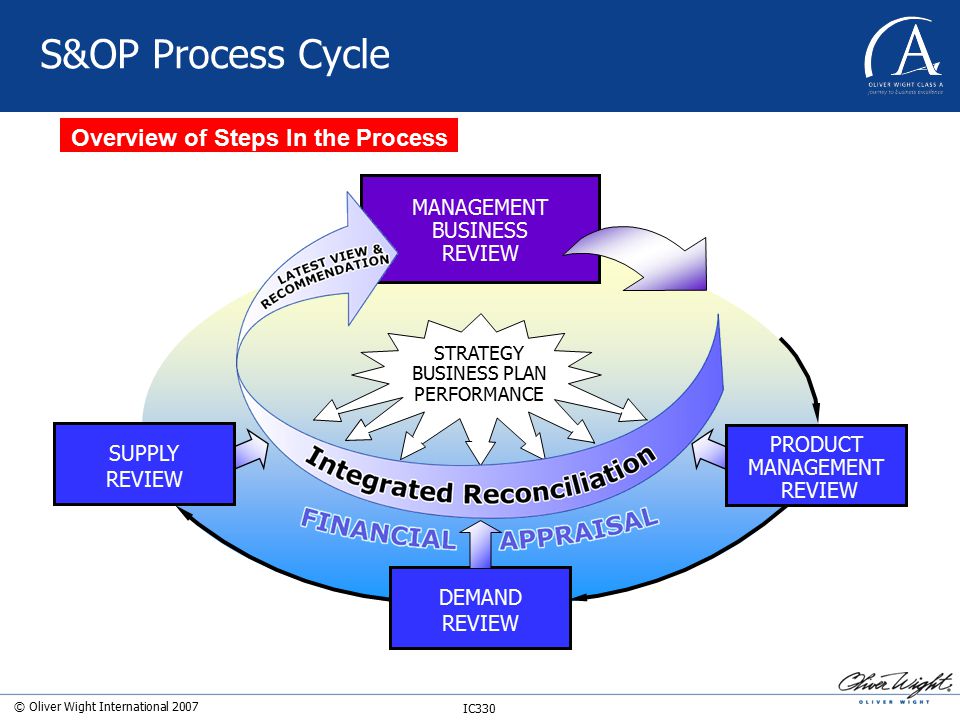

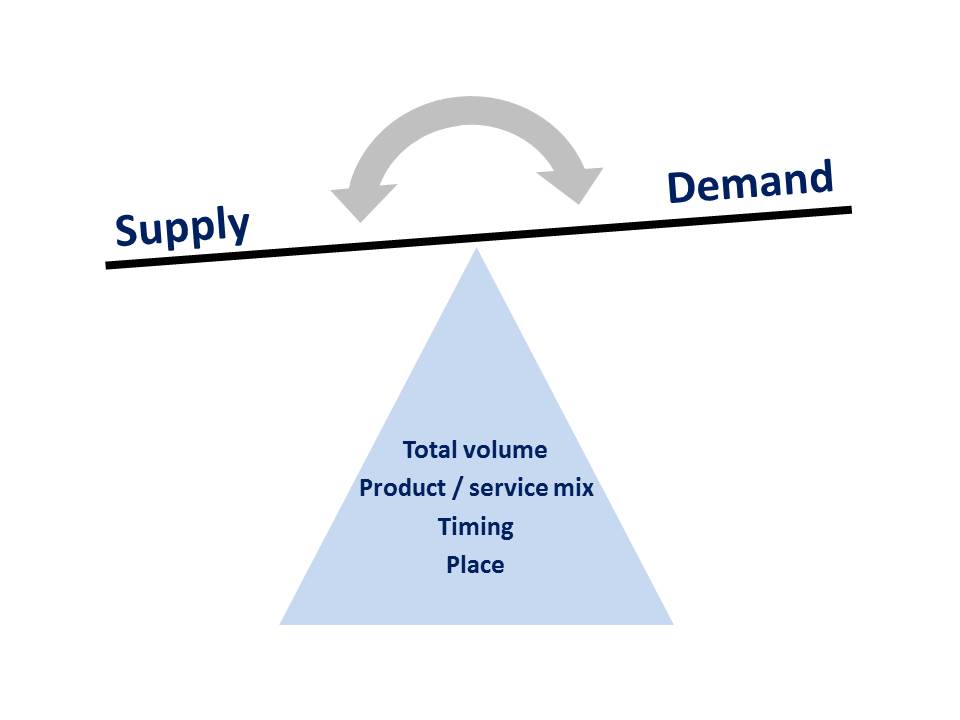

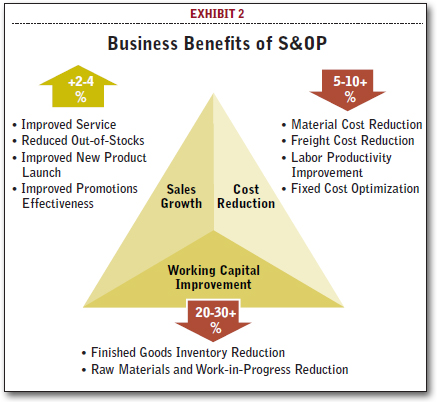

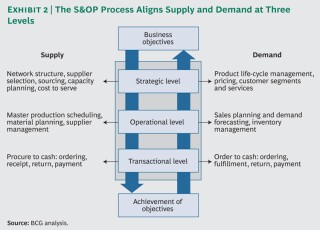

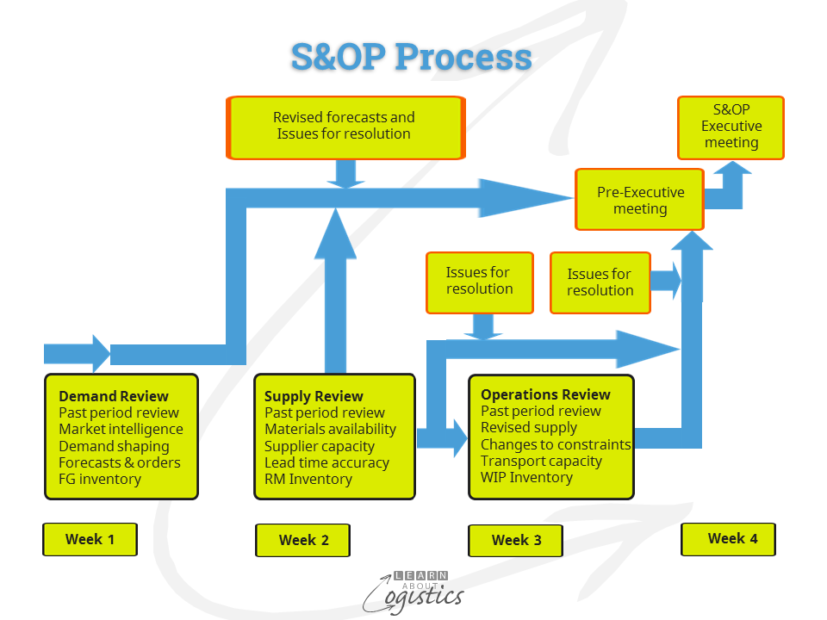

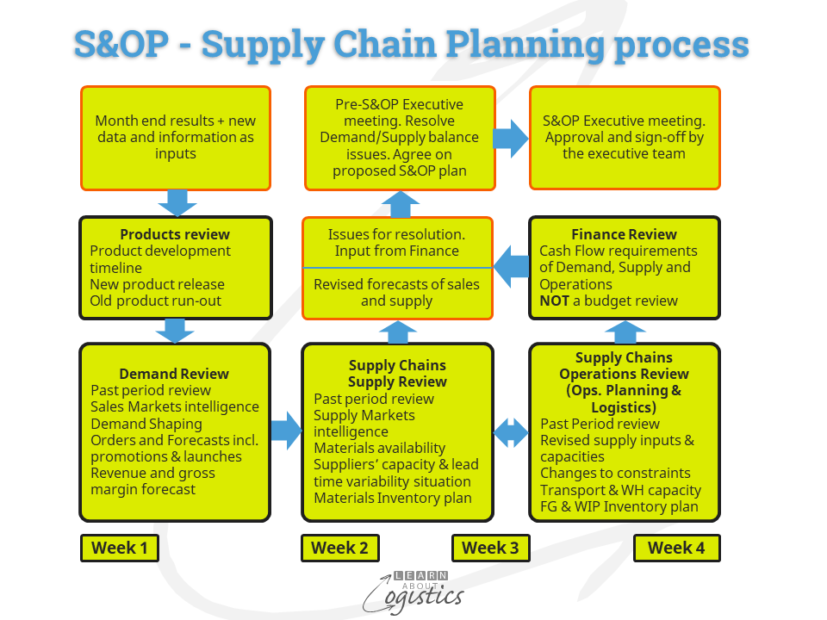

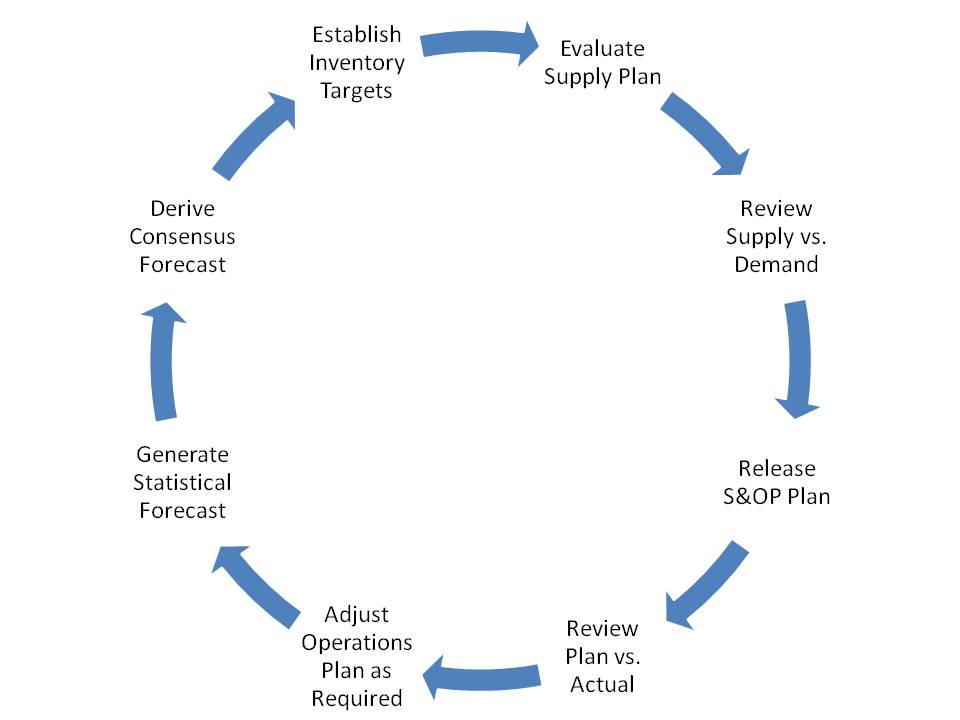

S&OE smooths the daytoday volatility for more controlled operations In Set Up Sales and Operations Execution Process to Support the S&OP Cycle Pukkila explains, "Because of the shortterm view to the supply chain and manufacturing management, the daytoday noise and volatility seem worse than it may be The result in many companies in this situation is that theySales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and finance S&OP is a structured planning process, based on a monthly cycle The objective is to improve the balance between future demands for the market's products and services, the organisation's resources and the supply of materials and services And, of course how the plan will be financed Implementing the S&OP process

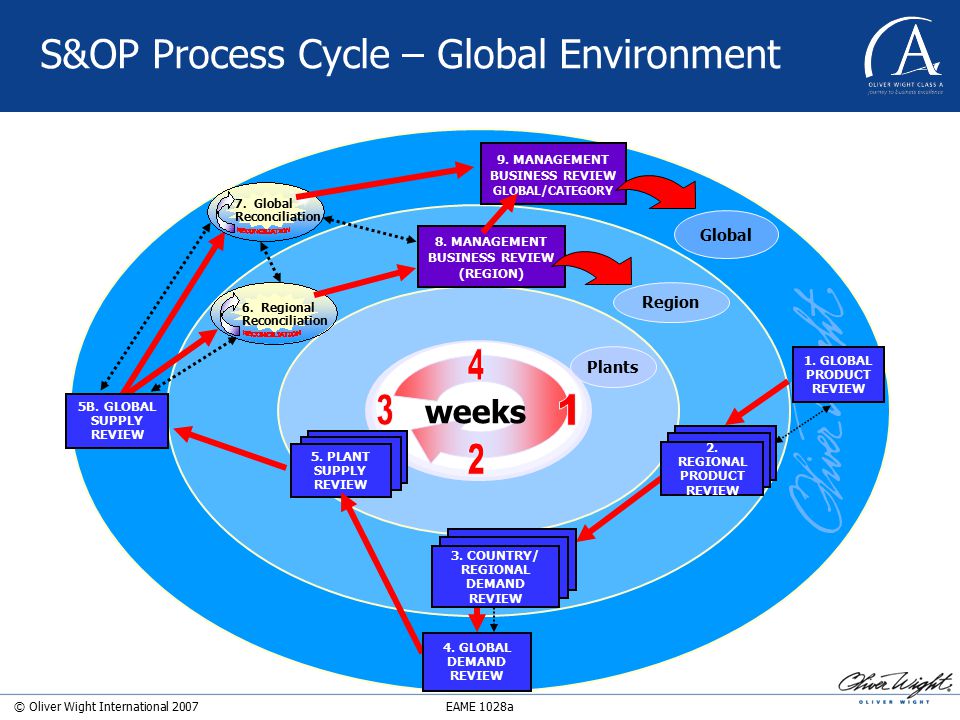

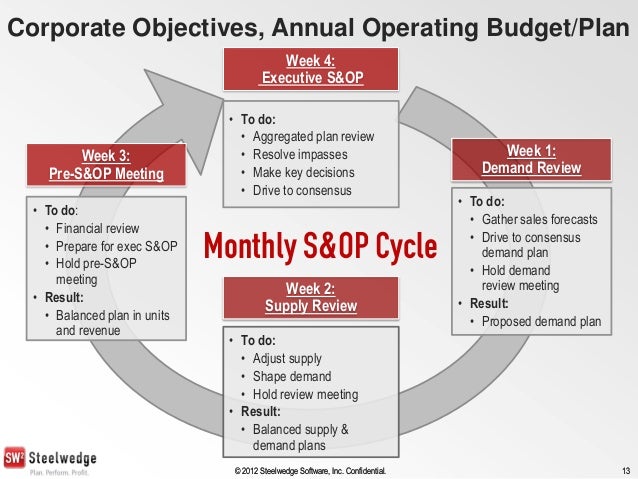

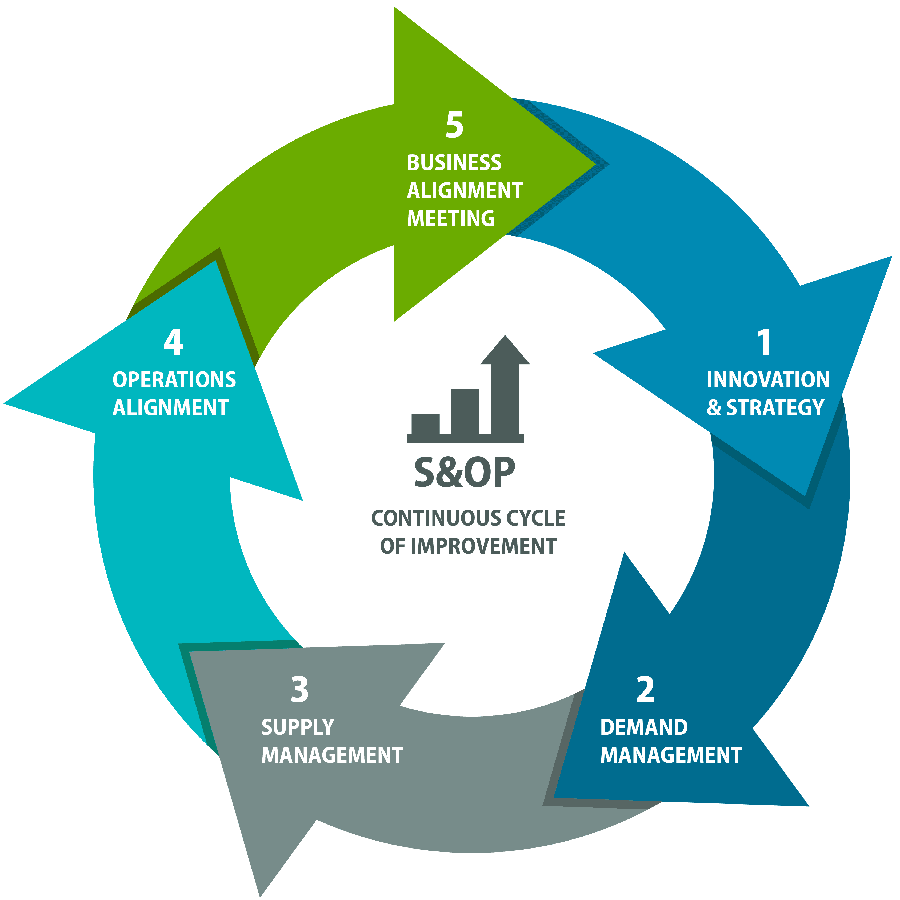

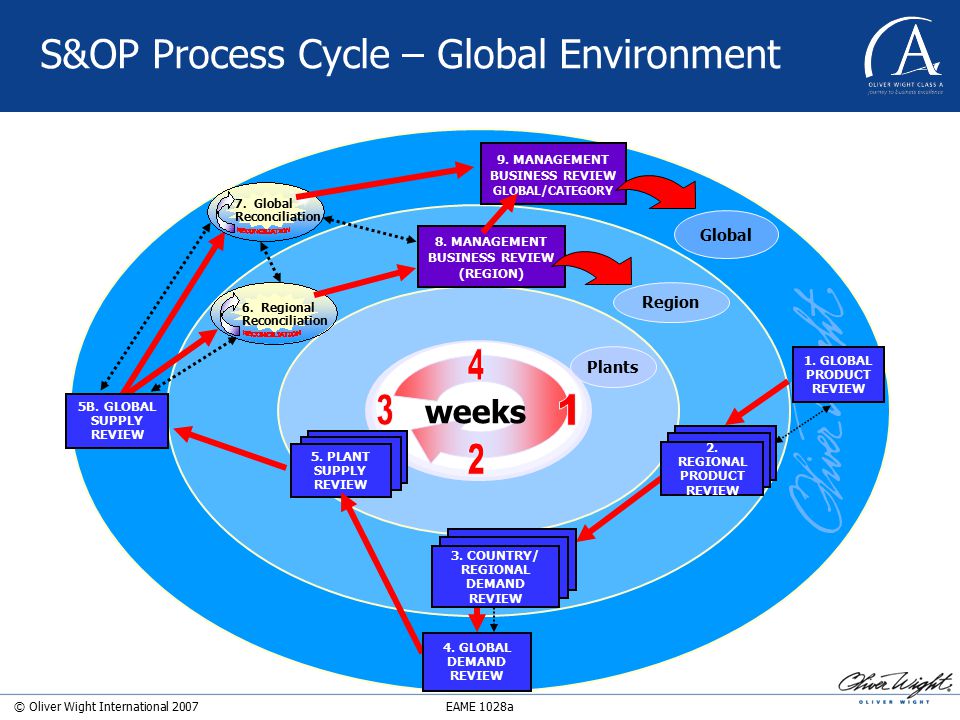

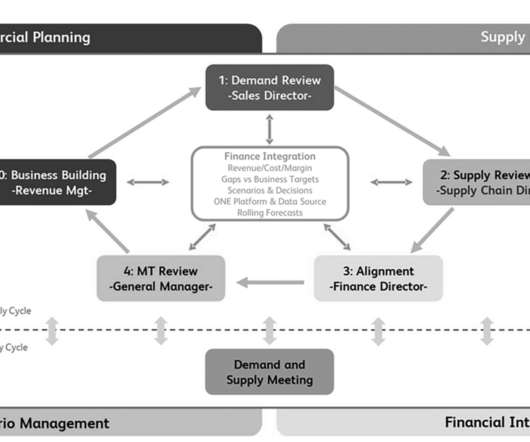

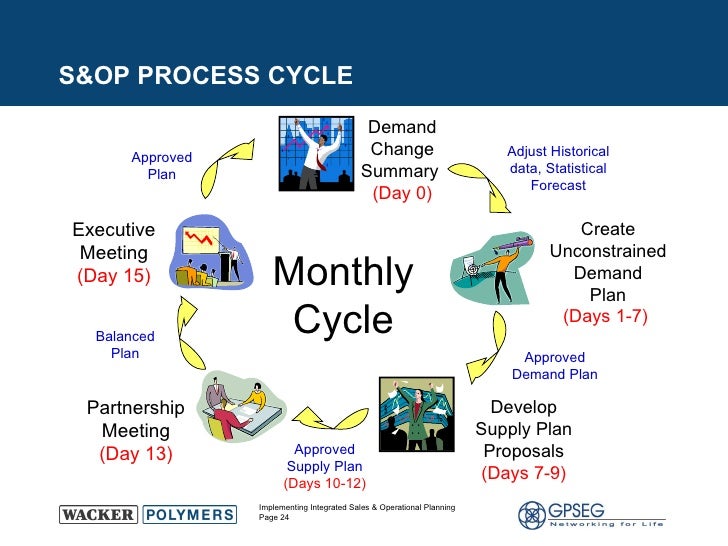

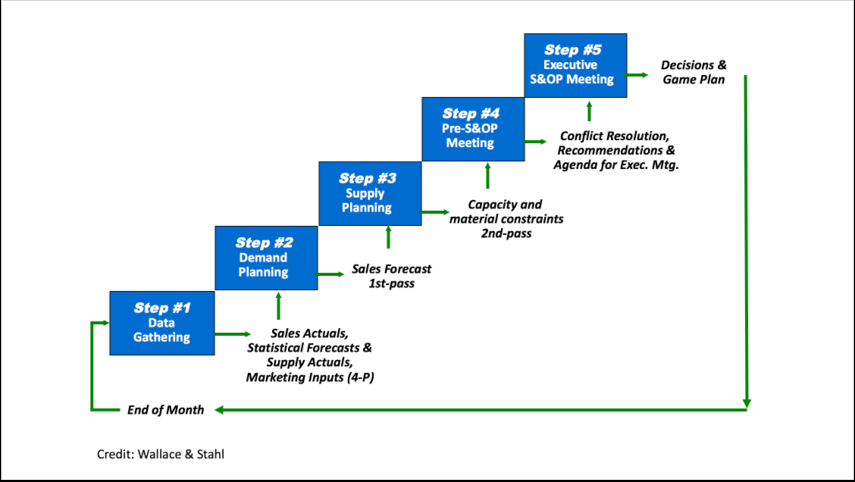

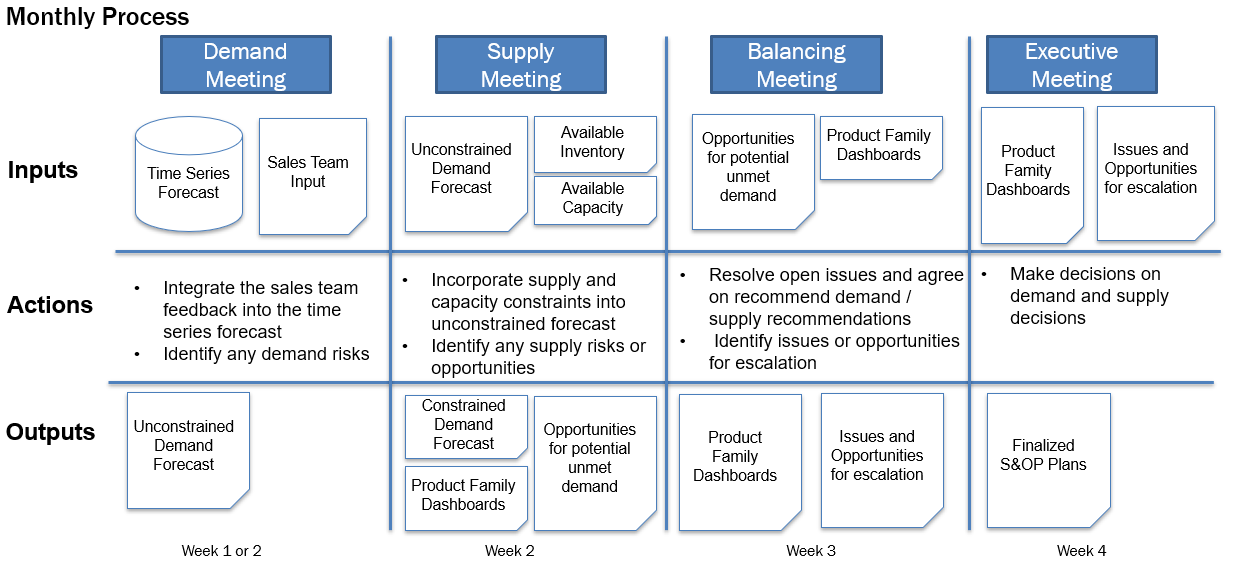

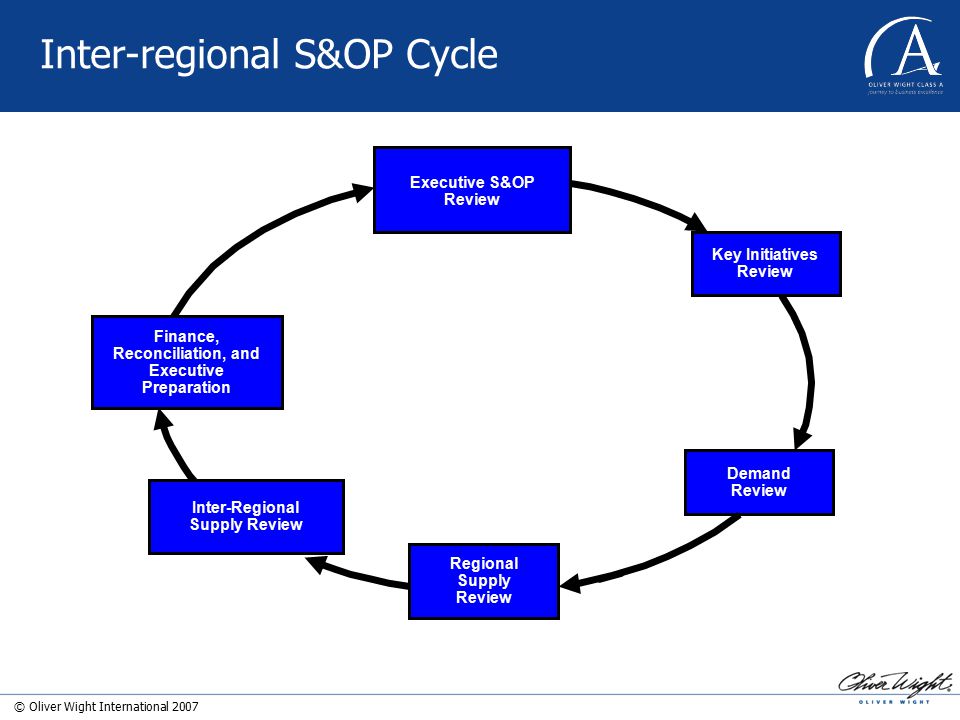

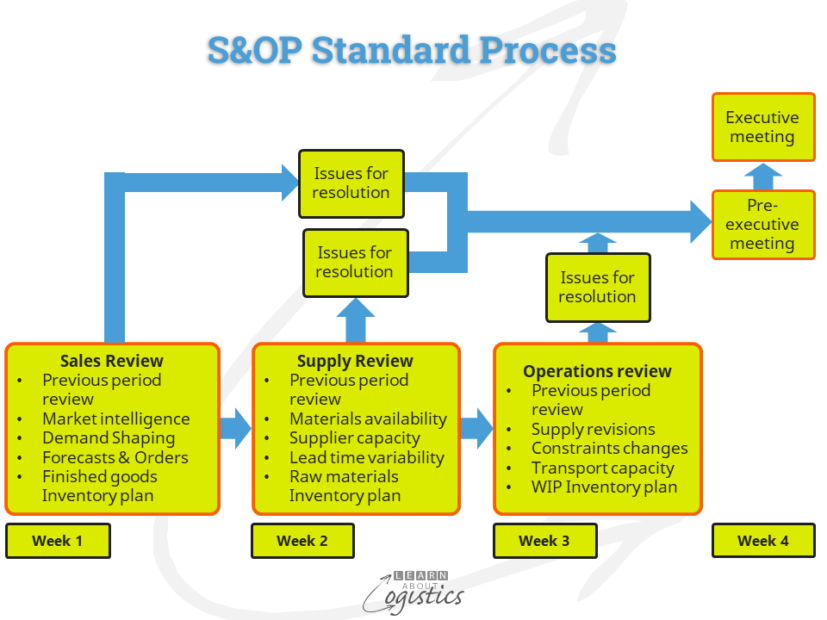

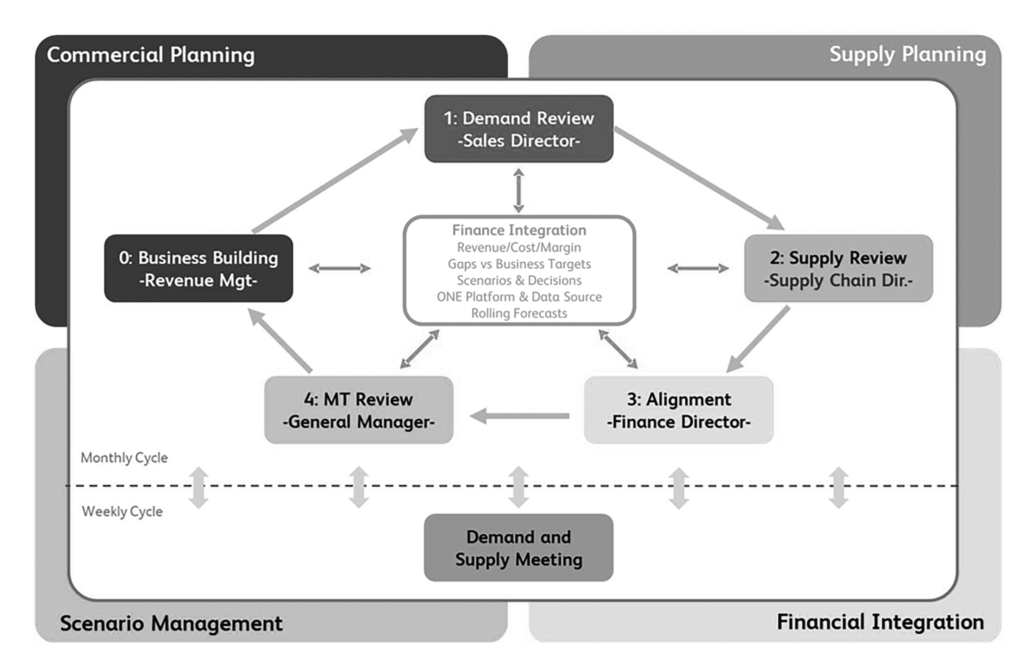

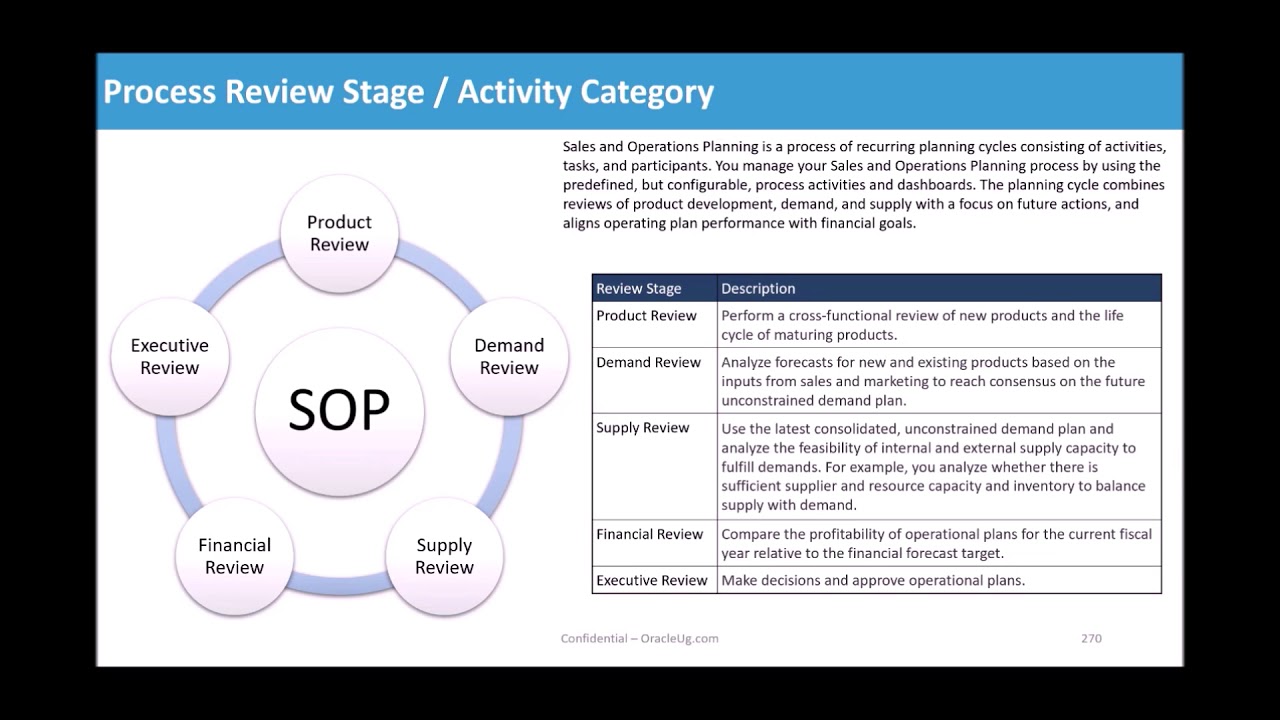

The S&OP process The process consists of focused review meetings for each discipline and an Executive meeting for decisions The diagram shows a standard model, but the actual number of review meetings are decided within each organisation For example Finance input is part of the preexecutive meeting The following steps will help your S&OP team successfully move toward this new model 1 Establish an S&OE process that supports the S&OP cycle This usually doesn't require starting from scratch Examine your current S&OP cycle and identify all the activities that should fall under the S&OE umbrellaS&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing the

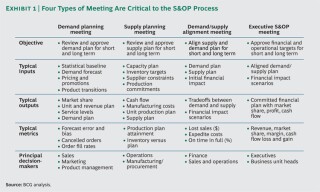

The S&OP leader will oversee this meeting/step in the process, but the Executive Sponsor is a required participant and will be needed to finalize all decisions/outcomes of the meeting Sample Agenda for Executive S&OP Meeting Five Steps to Making S&OP a WinWin for Your Entire Company The five conversations below can help your organization get started on making your best inventory investments 1 Start With Reliable Input and Accurate Data for Good DecisionMaking If your S&OP process is based on bad information either side will lose faith in the relationship5 STEP S&OP / IBP PROCESS • Master Data Management • Life Cycle Management • NPI Planning / EOL • Project Portfolio Mgt • Product "What Ifs" • Demand Plan Performance • Statistical Forecast • Consensus Demand • Demand Management • Demand "WhatIfs" • Capacity Planning • Constraint Management • Optimized inventory

Going Global With Sales And Operations Planning Ppt Video Online Download

Sales And Operations Planning Relex Solutions

The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a starting point, not much else can happen in the cycle There would be no supply and demand balancing exercise, plan valuation, or scenario There is a missing view on how the S&OP process (or as mentioned in the articale whichever name is used) are fitting in the total managerial steering model or governance used The S&OP process is but one of a total set of processes which enable a company or a unit of a company to steer and manage The default scenario in most businesses is that the S&OP process contains S&OE content This situation is not ideal, as both processes have different goals and requirements and should therefore be separated The first step for the supply chain planning leader is to identify the S&OE content in the S&OP process and move it to a separate agenda

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning Relex Solutions

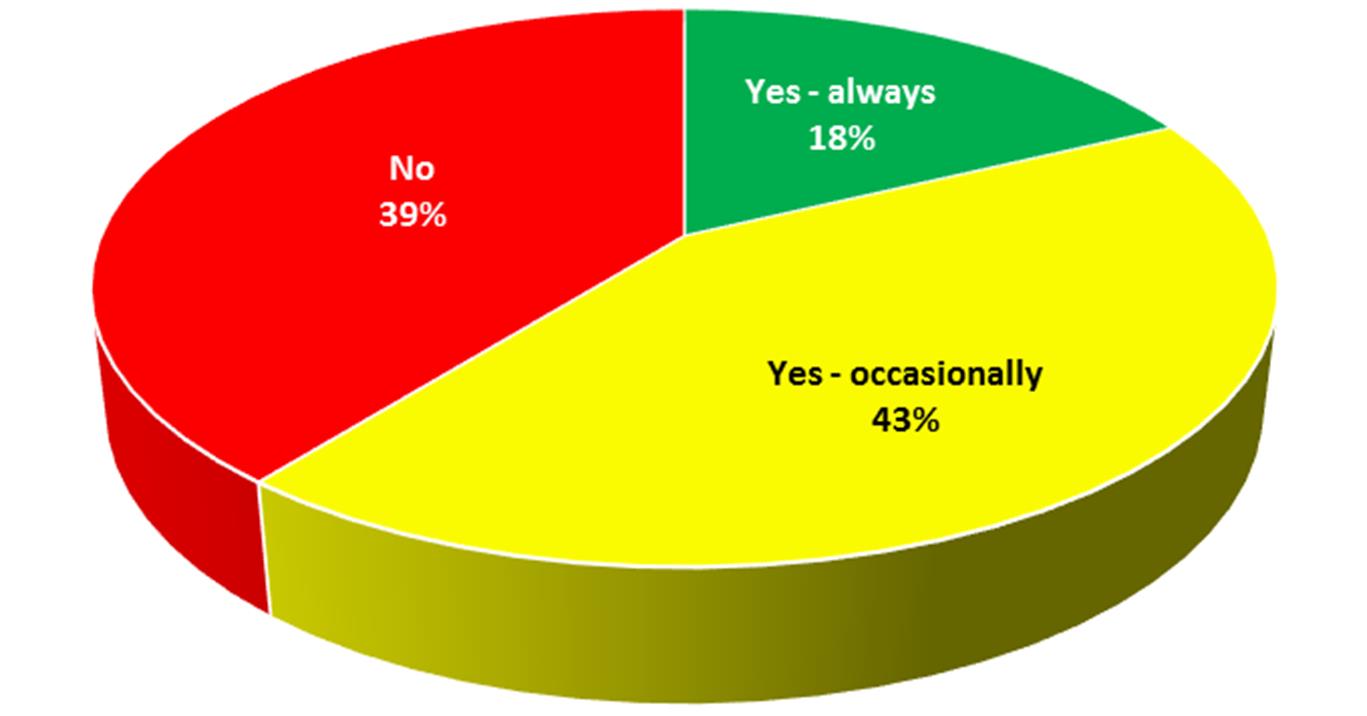

Inventory Optimization as an Essential Part of your S&OP At Solventure we take pride in being experts in designing and implementing Sales and Operations Planning Companies that have a good S&OP process can't imagine how to live without it It is the key instrument for the CEO to navigate the business along the budget towards its strategicAn S&OP process successful In Figure 1, there is a list of a dozen factors that can help lead to operating an S&OP process that maintains exceptional supply chain operational performance over time These factors are detailed below 1 Ongoing, Routine S&OP Meetings A key aspect of an S&OP process is that it is comprised of routine meetings• Fully implemented S&OP process • Decision makers participate in S&OP meetings • Organization follows S&OP process/plan • Further case analyses and interviews • Results in a nutshell • Many companies are trying (have tried), but only few succeed(ed) • Oftentimes process was implemented but not executed, ie back to business as

Sales And Operations Planning S Op Logistiikan Maailma

Who Should Own Sales And Operations Planning I Kinaxis

Set Up Sales and Operations Execution Process to Support the S&OP Cycle Published 28 January 16 ID G Analyst(s) Marko Pukkila Summary S&OE is an oftenoverlooked process that keeps manufacturers' S&OP from reaching its full potential S&OP is an oldline methodology that has been thoroughly updated to work in today's datadriven, technologyfocused manufacturing world And when you add technology to productions systems, you get a mountain of data to comb through, looking for ways toSteps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are

1

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

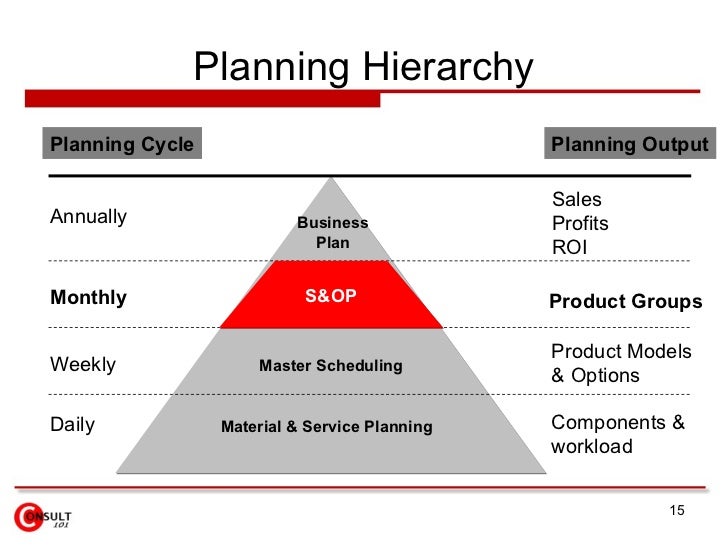

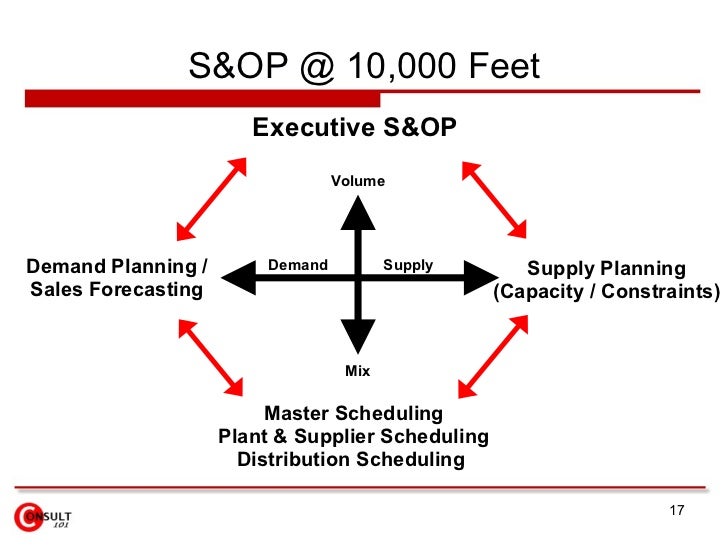

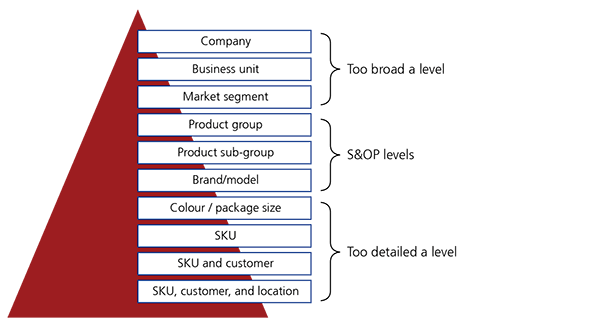

S&OP IS A JOURNEY Efficiency Effectiveness Optimization Stage 1 Reacting Stage 2 Anticipating Stage 3 Capable S&OP Stage 4 Optimized Planning Stage 5 Integrated Business Planning Maturity Levels based on Gartner's recommendations • Business plan drive forecast • Shortterm forecast • Aggregate S&OP Data • Offline Demand / Supply S&OP Process – what, where, when, which, who, why etc Annually Monthly Weekly Daily Sales Profits ROI Product Groups Product Models & Options Components & workload Planning Cycle Planning Output S&OP 16 S&OP @ 100,000 Feet Executive S&OP A process to reconcile, agree upon, and communicate the company game plan Product Development (NewS&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is to

S Op Process

S Op Introduction

Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operationalWhat Is Sales and Operations Planning (S&OP)?A good way of doing so is to include a product management review in the Sales and Operations Planning (S&OP) cycle By structurally involving product managers in the supply chain process, you can significantly reduce the risk of obsolete stock or service issues According to estimates, 7 out of 10 products are overforecast while 3 out of 10

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Successful Sales And Operations Planning In 5 Steps

The Executive S&OP planning cycle is monthly, with provisions for midperiod revisions when major changes occur Executive S&OP is an aggregate planning tool It focuses on aggregate volumes, and only rarely looks at issues of mix, ie individual products, stock keeping units, customer orders and so on The second step is to put in an alert mechanism that flags when the current S&OP process is out of date Most S&OP installations operate on a time cycle (monthly) and there is no mechanism in place to replan within a cycle This is like driving down the highway at a constant speed and ignoring all other vehiclesAs shown in the graphic, nearly all experts agree S&OP is a monthly process executed along a set weekly cycle, starting with collecting data from the previous end of month, and culminating in an executive meeting where the company comes to a consensus

Sales And Operations Planning Cycle Chainsequence Inc

Ppt Uk S Op Process Powerpoint Presentation Free Download Id

S&OP Performance By Dr David L Anderson September 08 Sales & Operations Planning (S&OP) activities are among the most important, but also the most complicated, tasks in supply chain management And we need not dwell on the complexityyou all know too well the difficulties of running successful S&OP processesEmail Address Subscribe to Supply Chain Game Changer Featuring Our 10 Best Inventory Management Articles! S&OP although simple in concept is very difficult to implement well Check this list of the essentials during your next S&OP cycle and if you can tick all the boxes, you're doing a good job and can move on to adding more KPIs and reports that ensure your S&OP process is strongly aligned to your strategy

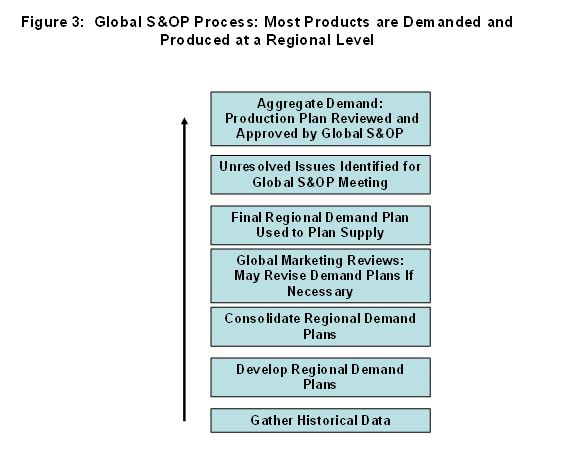

Going Global With Sales And Operations Planning Ppt Video Online Download

Getting To Grips With Sales And Operational Planning Bloor Research

S&OP facilitator helps discover why opinions differ while keeping the S&OP process on track S&OP Silos Potential silo conflicts outside of the S&OP process that hinder S&OP performance conflicts of interest, such as one department lowering its costs by offloading expenses onto another department failure to share information, or 4 Challenges in Starting and Sustaining a SIOP (S&OP) Business Process!5 Steps to Capture the Value of S&OP Let's say that you're working in sales planning and analysis for a yearold division of a global consumer electronics company, and you've just had a product launch that's the most unsuccessful in the company's history As a company, you'd been the number one player in the space up until this

S Op Process

1

Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted salesThis thesis studies Sales and Operations Planning (S&OP) in process industries S&OP is a planning process which has a role of balancing demand and supply at an aggregate level S&OP has traditionally been considered as a generic process meaning that it is independent from the context of the industry in which it is implemented Sales and Operations Planning (S&OP) Explained Sales and operations planning (S&OP) is a crucial process for any business — especially postCOVID, as plenty of businesses have seen pipeline shrink and sales cycles lengthen S&OP is about making sure that sales don't just generate revenues for the business, they generate profits

Metrics And S Op Supply Chain Brief

What Is S Op How S Op Works Demand Planning Com

Get Our EBOOK HERE A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful businessTraditionally, S&OP starts with the Demand Review – based on input provided by the sales organization – when in fact the first step should involve product management The fact that new product introductions (NPIs) and the phasing out of older products are often both overlooked, or at least are not on the radar during the S&OP process, is

Sales And Operations Planning S Op 101 Smartsheet

From S Op To Ibp The Discussion Continues

What Is S Op How S Op Works Demand Planning Com

What Is S Op Sales And Operations Planning Explained Anaplan

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Sales And Operations Planning

Executive S Op Case Study Presented At Gpseg

Smoother Execution Through S Op Supply Chain Management Review

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Five Steps To Get Started Supply Chain Shaman

What Is S Op Sales And Operations Planning Explained Anaplan

Improving Profitability With Sales Operations Planning Magellan Consulting Group

S Op Five Steps To Get Started Supply Chain Shaman

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

Aktuelles Von Aca Solutions Sales And Operations Planning To Industrialize The Aerospace Supply Chain

Supply Chain Graphic Of The Week The S Op Process

Does Your S Op Process Need Portfolio Review Nexview Consulting S Op Consulting

Software For Sales Operations Planning In Europe Supply Chain Movement

Achieve Excellence In Sales And Operations Planning Sapinsider

Driving Supply Chain Agility With S Op And S Oe I Kinaxis

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

S Op Process

What Are The Basic Elements Of The S Op Process Quora

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

What Is S Op How S Op Works Demand Planning Com

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Oracle Demantra Sales And Operations Planning User Guide

What Is Sales And Operations Planning S Op Plex Demandcaster

How S Op Improves Your Organization Tmc Fr

S Op And S Oe A Symbiotic Relationship

Implement The S Op Process For Supply Chain Success Learn About Logistics

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

2

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

Supply Chain Management Sales And Operations Planning S Op Improvement 27 Slide Powerpoint Flevypro Document Flevy

Sales And Operations Planning Process Self Assessment

1

S Op Five Steps To Get Started Supply Chain Shaman

Sales Operations Planning Consulting Supply Velocity

Sales Operations Execution S Oe Vs S Op Toolsgroup

Are Product Reviews Part Of Your S Op Process Plex Demandcaster

What Is One Plan S Op Arkieva

Pdf Sales And Operations Planning S Op An Overview

A Comprehensive Overview Of Sales And Operations Planning S Op

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning S Op Logistiikan Maailma

Sales And Operations Planning Report Do You Get Surprises

Going Global With Sales And Operations Planning Ppt Video Online Download

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales And Operations Planning

Achieve Excellence In Sales And Operations Planning Sapinsider

2

How Do Product Reviews Fit In The S Op Process Demand Planning Com

Tackling Life S Big Questions What Is S Op

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

Gartner Blog Network

Sales And Operations Planning Anaplan Community

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Integrating The S Op Process Go With The Flow Business 2 Community

What Are The Basic Elements Of The S Op Process Quora

Is Your Business Suffering From S Op Churn Optimity Anz

The S Op Cycle With Different Meetings đorđevic 17 P 44 Download Scientific Diagram

Smoother Execution Through S Op Supply Chain Management Review

Dp Vs S Op Process Flow

S Oe Where The Rubber Meets The Road The Pointy End Of S Op

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

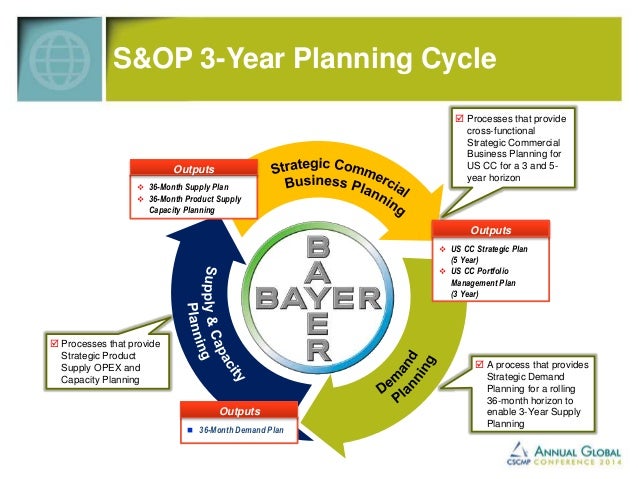

Cscmp 14 Bayer Putting The S Back In S Op

1

What Is S Op Sales And Operations Planning Sap Insights

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

What Is S Op How S Op Works Demand Planning Com

Sales Operations Planning Scpi

Sales And Operations Planning Relex Solutions

2

S Op Five Steps To Get Started Supply Chain Shaman

Tools Techniques For A Sustainable S Op Cycle Webinar Youtube

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

0 件のコメント:

コメントを投稿